الأشياء التي يجب مراعاتها عند اختيار الشركة المصنعة للمناديل

11 ديسمبر 2017

كيفية اختيار مُصنِّع مناديل قابلة للغسل

26 مارس 2023مقدمة:

أصبحت المناديل المبللة جزءًا أساسيًا من حياتنا ، من تنظيف الانسكابات والأوساخ إلى النظافة الشخصية. لكن هل تساءلت يومًا كيف يتم صنعها؟ في هذه المقالة ، سوف نستكشف عملية تصنيع المناديل المبللة والإجابة على بعض الأسئلة الشائعة حول إنتاجها وتأثيرها على البيئة.

What are wet wipes made of?

The materials used to make wet wipes can vary depending on their intended use. However, most wet wipes contain a combination of the following:

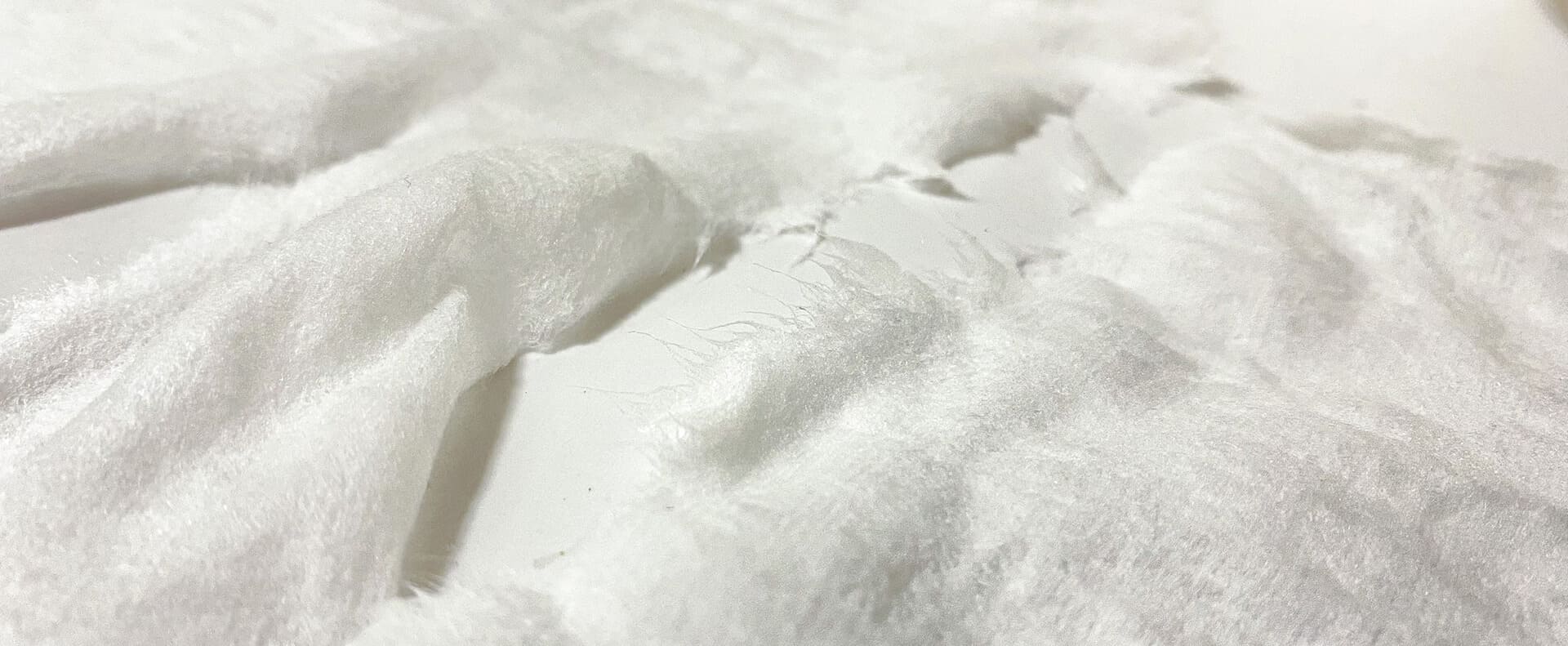

Non-woven fabric: This is the main component of wet wipes and is what gives them their softness and strength. Non-woven fabric is made from fibers that are bonded together using heat or chemicals. The most common fibers used in wet wipes are polyester and viscose blend, 100% viscose, there are also some brands using bamboo fiber, soy fiber.

Water: Wet wipes are soaked in a solution that typically contains water, a mild detergent, and other additives such as fragrances or preservatives, aloe, Glycerin, Chamomile etc.

Plastic resins: Some wet wipes may contain plastic resins such as polypropylene, which can help to reinforce the fabric and make it more durable.

How are flushable wet wipes made?

Flushable wet wipes are designed to disintegrate quickly when they come into contact with water. To achieve this, they are made using a combination of materials that are biodegradable and can break down easily. The manufacturing process for flushable wet wipes is similar to that of regular wet wipes, with the following key differences:

-

Biodegradable fibers: Flushable wet wipes are made from biodegradable fibers such as cellulose or bamboo, which can break down quickly in water.

-

Water-soluble binders: The fibers in flushable wet wipes are held together using water-soluble binders such as polyvinyl alcohol. These binders dissolve in water, allowing the wipes to break apart easily.

-

Thicker fabric: To prevent the wipes from falling apart during use, flushable wet wipes are typically made from thicker fabric than regular wet wipes. This thicker fabric also helps to trap solids and prevent them from clogging pipes.

Are wet wipes really biodegradable?

While many wet wipes are marketed as biodegradable or flushable, the reality is more complex. Some wet wipes contain plastic resins that can take hundreds of years to break down, while others may not disintegrate as quickly as advertised. Additionally, even biodegradable wet wipes can cause problems if they are not disposed of properly. If wet wipes end up in landfills, they may not break down due to the lack of oxygen and sunlight. To minimize the environmental impact of wet wipes, it is important to look for products that are certified as biodegradable by reputable organizations.

Are wet wipes made from paper?

While wet wipes may look and feel like paper, they are actually made from non-woven fabric, which is a different material. Non-woven fabric is made by bonding fibers together using heat or chemicals, while paper is made from wood pulp that is pressed and dried. Some wet wipes may contain a small amount of paper, but the majority of the material is non-woven fabric.

Types of Wet Wipes:

There are many different types of wipes available in the market, each designed for a specific purpose. Some common types of wipes include:

-

Baby wipes: These are designed for use on a baby's delicate skin.

-

Antibacterial wipes: These are formulated to kill germs and bacteria and are commonly used for cleaning surfaces and hands.

-

Makeup removal wipes: These are designed to remove makeup and dirt from the face.

-

Wet floor wipes: These are designed for cleaning floors and other hard surfaces.

-

Personal hygiene wipes: These are designed for use on the body to help freshen up.

-

Flushable wipes: These are designed to be flushed down the toilet and disintegrate quickly in water.

-

Disinfectant wipes: These are designed to kill germs and bacteria and are commonly used for cleaning surfaces and hands.

-

Glass cleaning wipes: These are designed for cleaning glass surfaces.

-

Furniture wipes: These are designed for cleaning and dusting furniture.

-

Pet wipes: These are designed for cleaning pets and can be used on fur, paws, and other areas.

There are many other types of wipes available as well, depending on the manufacturer and the intended use. It is important to choose the right type of wipe for the job to ensure effective cleaning and hygiene.

The Manufacturing Process of Wet Wipes:

The production of wet wipes involves several steps that are carefully executed to ensure the final product is of high quality. The following are the basic steps involved in the manufacturing of wet wipes:

-

Preparation of the Solution: The first step is to prepare the solution that the wipes will be soaked in. The solution usually contains water, a mild detergent, and other additives such as fragrances, preservatives, or moisturizers.

-

Cutting the Fabric: The fabric used to make the wet wipes is cut into the desired size and shape. The most common material used for wet wipes is non-woven fabric, which is made by bonding fibers together using heat or chemicals.

-

Soaking the Fabric: The cut fabric is then soaked in the prepared solution to ensure that it is fully saturated. The amount of solution used will depend on the desired wetness of the wipes.

-

Folding and Packaging: Once the fabric is fully saturated, it is folded and packaged. The packaging can be in the form of a canister, sachet, or plastic container, depending on the product's intended use.

How are wet wipes producing in QIMEI - Autometic Production Line

خاتمة:

Wet wipes are a versatile and convenient product that has become a household staple. The manufacturing process involves several steps, including preparing the solution, cutting the fabric, soaking the fabric, and packaging. The materials used to make wet wipes are primarily non-woven fabric, water, and additives. Understanding the manufacturing process and materials used can help consumers make informed decisions when purchasing wet wipes.