Type de tissu tissé Spunlace : polyester, mélange de poly-viscose, fibre de bambou, pâte de bois (jetable dans les toilettes), coton ou fibre de soja (biodégradable)

Plat ou texturé (votre propre LOGO est disponible)

Grammage: 30-80gsm

1/10/30/80/100/120/160 pièces/paquet

Les lingettes parfumées à usage unique sont généralement de plus petite taille, allant de quelques pouces carrés à quelques pieds carrés, tandis que les lingettes plus grandes et multi-usages peuvent mesurer plusieurs pieds de longueur et de largeur.

1. Sac refermable en plastique : Il s'agit du type d'emballage de lingettes humides le plus courant. Il est fait de plastique et possède une bande refermable sur le dessus pour garder les lingettes fraîches et humides.

2. Conteneur à couvercle rabattable : Ce type d'emballage consiste en un contenant en plastique avec un couvercle rabattable qui peut être ouvert et fermé pour accéder aux lingettes.

3. Emballage souple avec couvercle rabattable en plastique : Semblable au récipient à couvercle rabattable, cet emballage est livré dans un emballage souple et possède un couvercle rabattable en plastique pour un accès facile.

4. Distributeur pop-up : Ce type d'emballage est doté d'un mécanisme de distribution pop-up qui sort une lingette à la fois.

5. Pack de voyage : Un petit emballage conçu pour une utilisation en déplacement, il est souvent livré avec une fermeture à pression en plastique.

6. Emballage à usage unique : ces lingettes humides sont présentées dans de petits paquets scellés, pratiques pour les voyages ou les activités de plein air.

7. Sac de recharge : cet emballage de plus grande taille est conçu pour remplir d'autres contenants de lingettes humides et a généralement une ouverture refermable.

Tissu non tissé : C'est le matériau utilisé pour fabriquer la lingette elle-même. Les tissus non tissés sont généralement fabriqués à partir de fibres synthétiques comme le polyester ou le polypropylène, ou de fibres naturelles comme le coton ou le bambou.

Eau : L'eau est utilisée pour humidifier les lingettes et servir de support aux autres ingrédients.

Parfums : les lingettes parfumées sont infusées de parfums ou de parfums pour fournir une odeur fraîche ou propre. Ces parfums peuvent être synthétiques ou dérivés de sources naturelles.

Conservateurs : Des conservateurs sont ajoutés aux lingettes parfumées pour empêcher la croissance de bactéries et de moisissures. Les conservateurs couramment utilisés dans les lingettes comprennent le méthylparabène et le propylparabène.

Tensioactifs : Les tensioactifs sont utilisés pour aider à nettoyer les surfaces en éliminant la saleté et la crasse. Ils aident également à répartir le parfum uniformément sur toute la lingette. Les tensioactifs couramment utilisés dans les lingettes parfumées comprennent le laureth sulfate de sodium et la cocamidopropylbétaïne.

Émulsifiants : les émulsifiants sont utilisés pour aider à mélanger des ingrédients qui ne se mélangent pas naturellement, comme l'huile et l'eau. Ils contribuent à garantir que le parfum et les tensioactifs sont répartis uniformément dans toute la lingette.

Ajusteurs de pH : des ajusteurs de pH sont utilisés pour garantir que la lingette a le niveau de pH approprié pour l'utilisation prévue. Par exemple, les lingettes conçues pour être utilisées sur la peau peuvent avoir un pH plus bas pour éviter les irritations, tandis que les lingettes conçues pour être utilisées sur des surfaces dures peuvent avoir un pH plus élevé pour améliorer l'efficacité du nettoyage. Les ajusteurs de pH couramment utilisés dans les lingettes parfumées comprennent l'acide citrique et l'hydroxyde de sodium.

Bonnes pratiques de fabrication (BPF) : les BPF sont un ensemble de directives qui garantissent que les produits sont fabriqués de manière cohérente et répondent aux normes de qualité. La conformité aux BPF est souvent exigée par les agences de réglementation de nombreux pays.

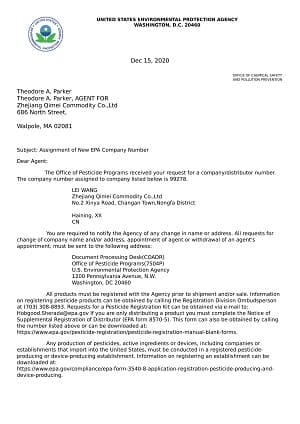

Réglementations de l'Environmental Protection Agency (EPA) : Aux États-Unis, les lingettes parfumées commercialisées comme désinfectants sont soumises aux réglementations de l'EPA. Ces réglementations obligent les fabricants à enregistrer leurs produits auprès de l'EPA et à garantir qu'ils répondent à des normes d'efficacité et de sécurité spécifiques.

Réglementation de l'Union européenne : Dans l'Union européenne, les lingettes parfumées sont soumises au Règlement sur les produits biocides (RPB), qui oblige les fabricants à enregistrer leurs produits et à démontrer leur sécurité et leur efficacité.

Certifications de l'Organisation internationale de normalisation (ISO) : les certifications ISO, telles que ISO 9001 et ISO 13485, sont des normes reconnues à l'échelle internationale qui démontrent l'engagement d'un fabricant en matière de gestion de la qualité et de sécurité des produits.

Fiches de données de sécurité (FDS) : les fabricants sont tenus de fournir des fiches de données de sécurité pour leurs produits. Ces documents contiennent des informations sur les ingrédients, les dangers potentiels et les procédures de manipulation sûre du produit.